The manufacturing business involves a lot of precision and efficiency. It all comes together when you are dealing well with the stock and materials. The Importance of inventory management for manufacturing is always paramount. Thus, a better solution is to maintain inventory levels.

This article sheds light on why you need inventory management for your manufacturing business. The reasons are necessary to understand the need for an inventory management solution.

Cost Savings

Cost-saving is the main goal of any business. The same follows in the manufacturing business as well. Inventory management prioritizes cost-saving by maintaining inventory levels. You can save money on stock that is already available and, thus, avoid any material in excess.

You may need to pay costs for transport of the material, warehouse charges, maintenance charges, and a lot more. This happens when you are not aware of the stock quantity. Inventory management updates you with real-time data on stock levels.

Cost savings help you allocate resources to other activities of utmost importance. Hence, inventory management is a better solution for cost-saving.

Prevent Stockouts

Apart from excess stocks, stockouts can be another problem. It can hamper routine work and result in more expenses. You ask how? If you run out of stock, you may need to buy a small quantity urgently. This can lead to more expenses.

And the hampered work can take more time in manufacturing. Your clients may not appreciate the delay in such processes. It can damage your company’s reputation. Therefore, in today’s era, it is necessary that you keep tracking the stocks on a real-time basis.

Inventory management notifies customers when the stock quantity decreases. It does it all automatically, so there is no chance of missing anything.

On-Time Deliveries

When you finish manufacturing work on time, you complete on-time deliveries. This leads to customer satisfaction. But how do you manage working on time? Let inventory management handle it.

It helps you create a schedule for all the manufacturing processes, and thus, you achieve deadlines. If you want to stay ahead, being on time should be your goal. Time and tide wait for none, and so do clients.

Delivering the goods on or before time creates a positive image of your business. For this, following a schedule is a must. Inventory management creates schedules and keeps updating tasks that are done.

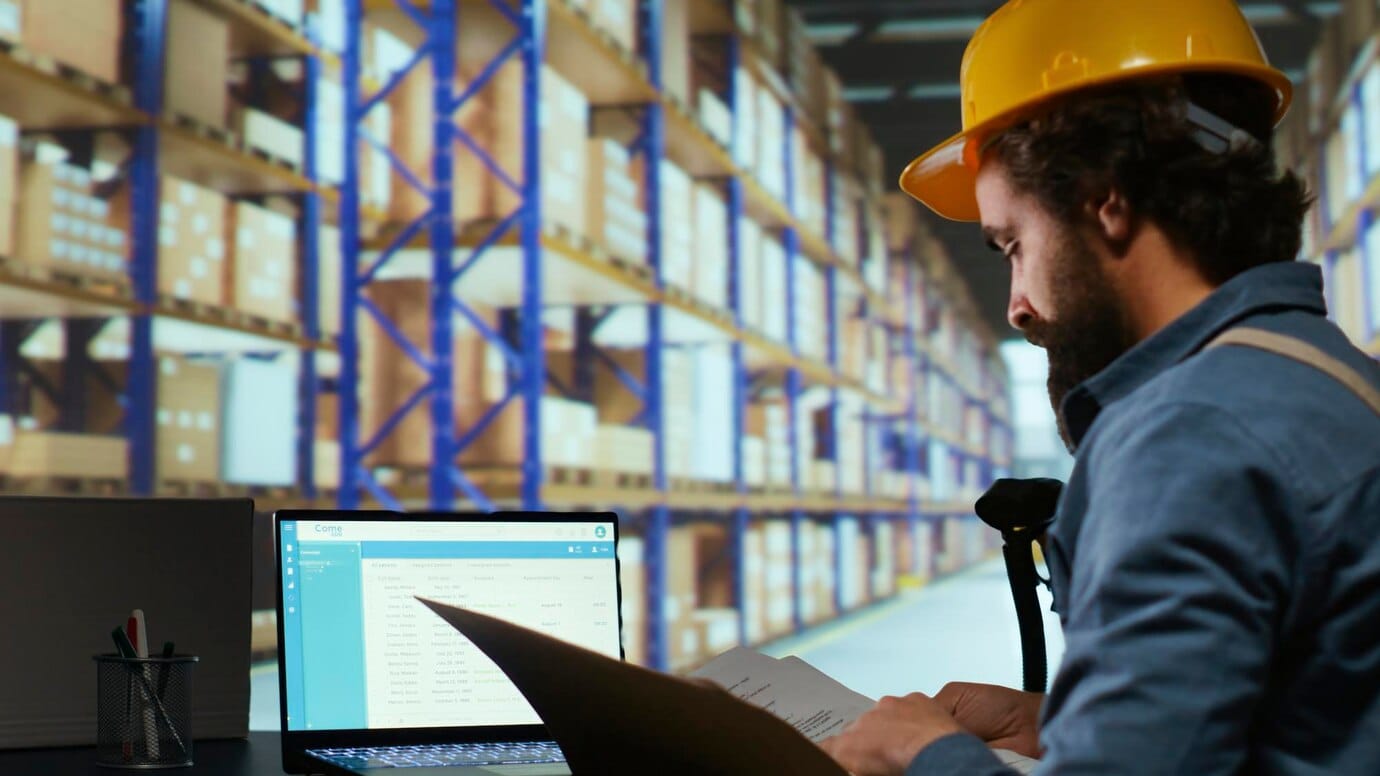

Optimize Production Planning

To maximize operational efficiency, you need proper tools. These tools and insights are available through inventory management. A well-organised database helps you make better decisions and plan accordingly.

Inventory management streamlines all the processes, identifies ongoing trends, and updates you based on the insights. This way, you get to optimize production planning. From manufacturing schedules to order delivery, you can track everything in inventory management.

Conclusion

Inventory management is the need of the hour in the manufacturing business. it keeps you ahead in the game and makes sure your business attains maximum customer satisfaction. From cost-saving to optimised production planning, it takes care of it all.

Contact Blue Lotus 360 to get inventory management system for manufacturing industry.