Implementing Blue Lotus 360 Warehouse Management System has been a game-changer for our operations. From streamlining inventory management to optimizing workflow efficiency, the system has exceeded our expectations. With real-time visibility and enhanced traceability, we've reduced errors and significantly improved order fulfillment speed. The user-friendly interface and advanced technology have allowed us to cut operating costs while maximizing productivity. Blue Lotus 360 truly delivered on its promise to transform our warehouse operations, and we couldn't be happier with the results.

Emily Roberts

Operations Manager - NextStep RetailAdopting Blue Lotus 360 Warehouse Management System has completely transformed the way we manage our warehouse. The system’s real-time inventory tracking and automated processes have drastically reduced the time spent on manual tasks, allowing us to focus on scaling our business. We've experienced a significant improvement in order accuracy, and our team’s productivity has surged. The intuitive interface made the implementation process seamless, and the support from the Blue Lotus 360 team has been exceptional. We’re now operating with greater efficiency and cost-effectiveness than ever before.

Warehouse Operations Lead

PrimeTech Industries

Revolutionize Warehouse Operations with

Blue Lotus 360

WMS.

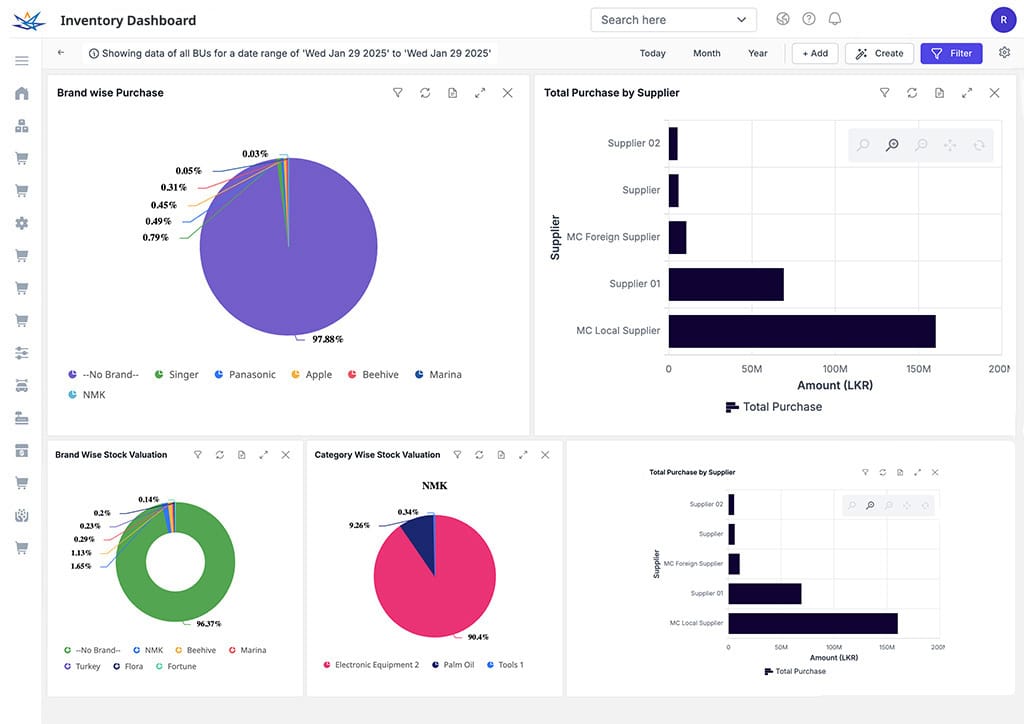

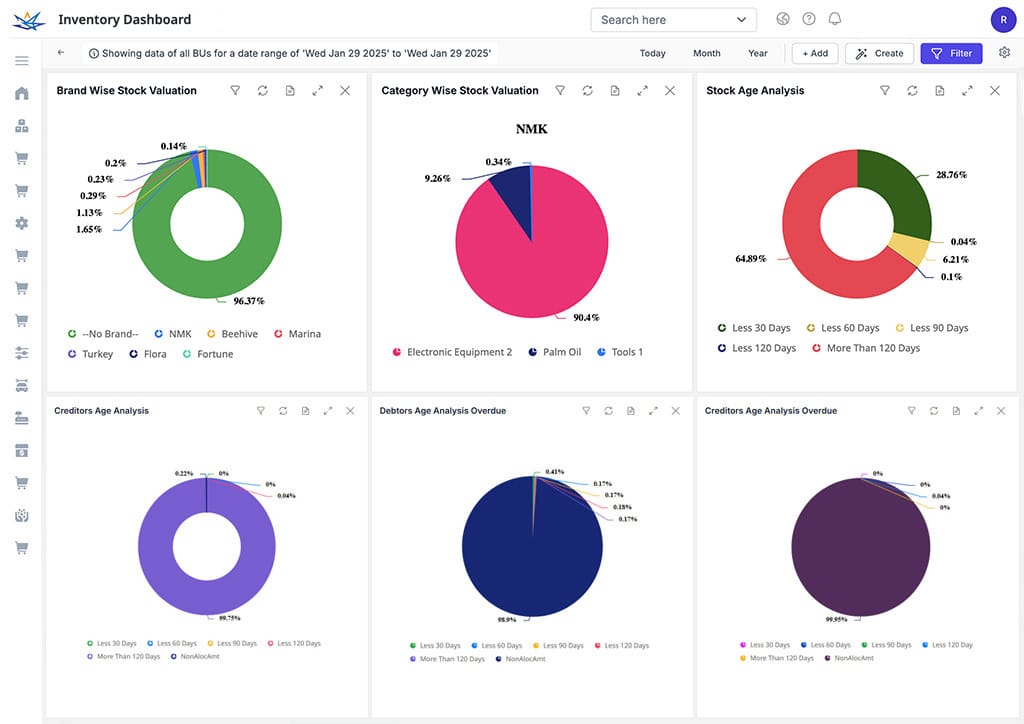

Managing a warehouse manually is inefficient and costly. Blue Lotus 360 WMS boosts productivity and reduces operating costs by offering secure storage, fast handling, and accurate inventory control. It optimizes the movement of raw materials, WIP, and finished goods, while enhancing visibility and traceability.

Manual operations can lead to errors, delays, and increased labor costs. Our WMS seamlessly integrates with existing processes, providing real-time inventory updates, automated order fulfillment, and better supply chain visibility. It helps reduce waste, prevent stockouts, and improve customer satisfaction through accurate order processing and timely delivery in the UK.

Prepare ASN Data

Efficiently manage and track incoming shipments with advanced shipping note preparation, ensuring accuracy and visibility.

Receiving Goods

Automate receiving processes to validate shipments, capture detailed data, and update inventory in real-time.

Stock Update

Maintain accurate and current inventory records by updating stock levels automatically after each transaction.

Inspection

Ensure quality with automated inspection processes, flagging items based on predefined criteria and maintaining traceability.

Put Away

Optimize storage by assigning ideal locations using item characteristics, warehouse layout, and demand frequency.

Comprehensive Bin Management

Maximize efficiency with detailed bin tracking, enabling multiple product storage and real-time updates.

Creating Delivery Orders

Simplify delivery order generation from sales or material requisition notes, ensuring accurate and timely shipments.

Picking

Reduce errors with directed picking lists, barcode scanning, and mobile devices for efficient order preparation.

Shipping

Expedite shipping with label generation, carrier scheduling, and tracking to guarantee reliable deliveries.

Modules

Efficient modules to streamline warehouse operations, from receiving goods to shipping seamlessly.

Prepare ASN Data

Receiving Goods

Inspection

Put Away

Stock Update

Stock Hold

Stock Un-Hold

Comprehensive Bin Management

Bin Layout Dashboard

Creating Delivery Order

Picking

Packing

Inspection

Shipping

Streamlined Warehouse Solutions for Every Industry in the UK

Our Warehouse Management System delivers tailored solutions to enhance efficiency, accuracy, and operations across various industries in the UK.

Retail and E-commerce

Efficiently manage large inventories and ensure fast, accurate order fulfillment.

Manufacturing

Track raw materials, work-in-progress, and finished goods for optimized production.

Logistics and Distribution

Streamline operations in distribution centers with real-time inventory tracking.

Food and Beverage

Ensure compliance and traceability for perishable and regulated goods.

Pharmaceuticals and Healthcare

Maintain strict inventory control and regulatory compliance for sensitive products.

Automotive

Manage high-value parts with precision and reduce downtime through efficient distribution.

Electronics and Technology

Handle small, high-value items with accuracy and streamline repair/return processes.

Apparel and Textiles

Optimize inventory for fast-changing trends and meet retail shipment deadlines.

Chemicals and Raw Materials

Safely store hazardous materials and track inventory for production and export.

Why Choose

Blue Lotus 360

Warehouse Management System for Your Business in the United Kingdom?

Implementing Blue Lotus 360 WMS in the UK helps transform your warehouse into a highly efficient, streamlined, and productive part of your supply chain.

Improved Accuracy and Reduced Errors

A WMS automates manual processes, reducing human errors and ensuring accurate inventory counts, order fulfillment, and shipping.

Enhanced Productivity

Automating routine tasks and optimizing workflows helps increase productivity, allowing your staff to focus on more strategic activities.

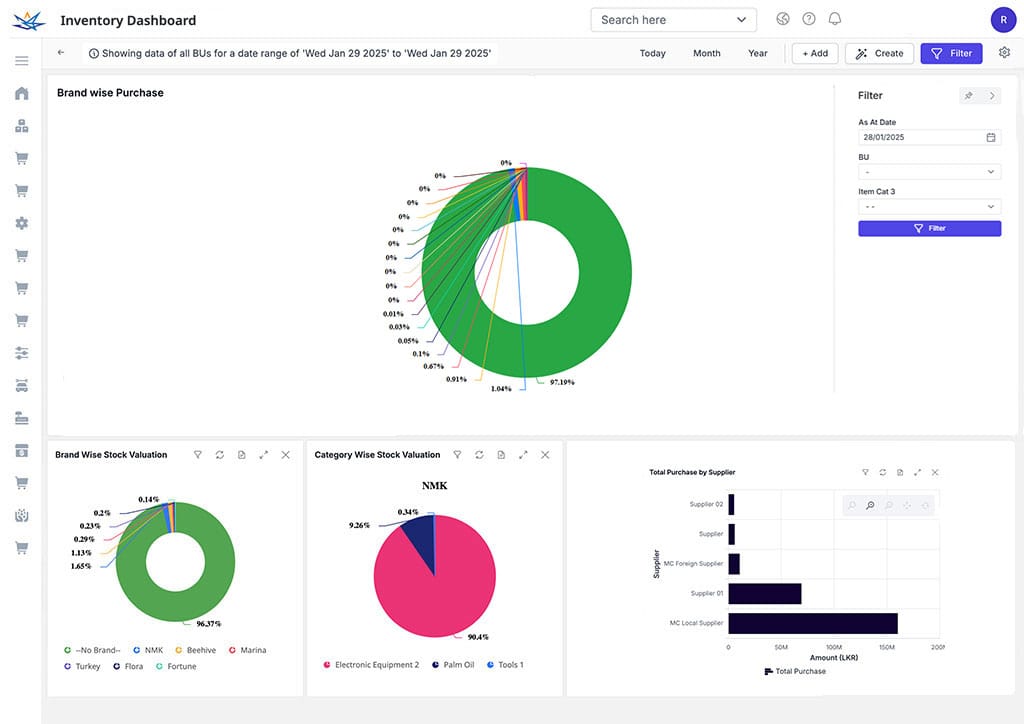

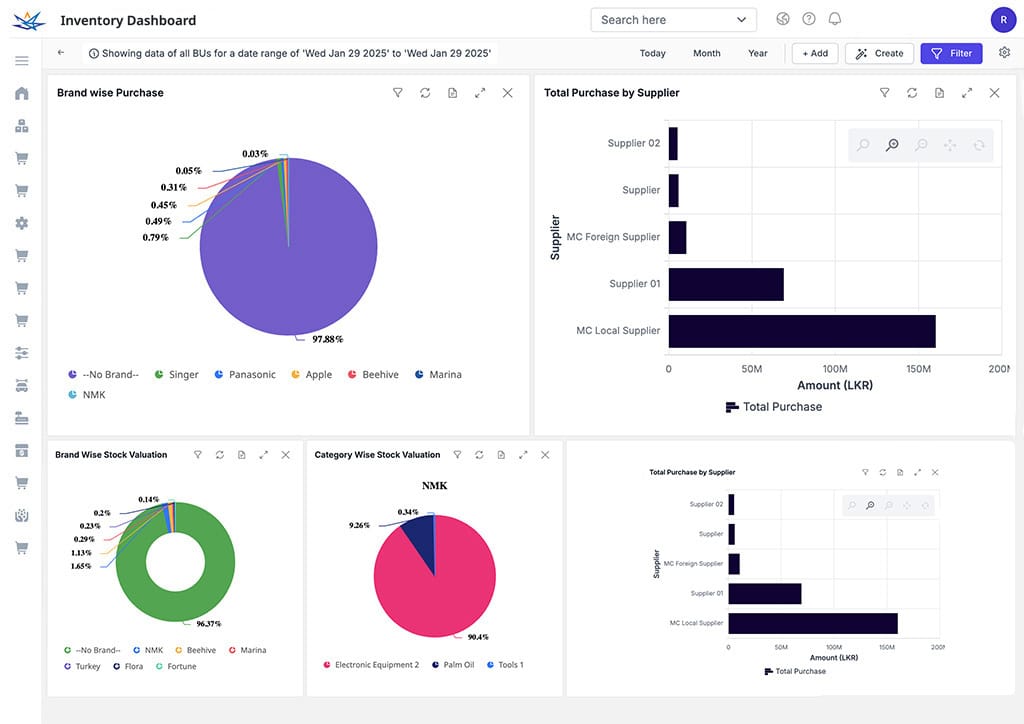

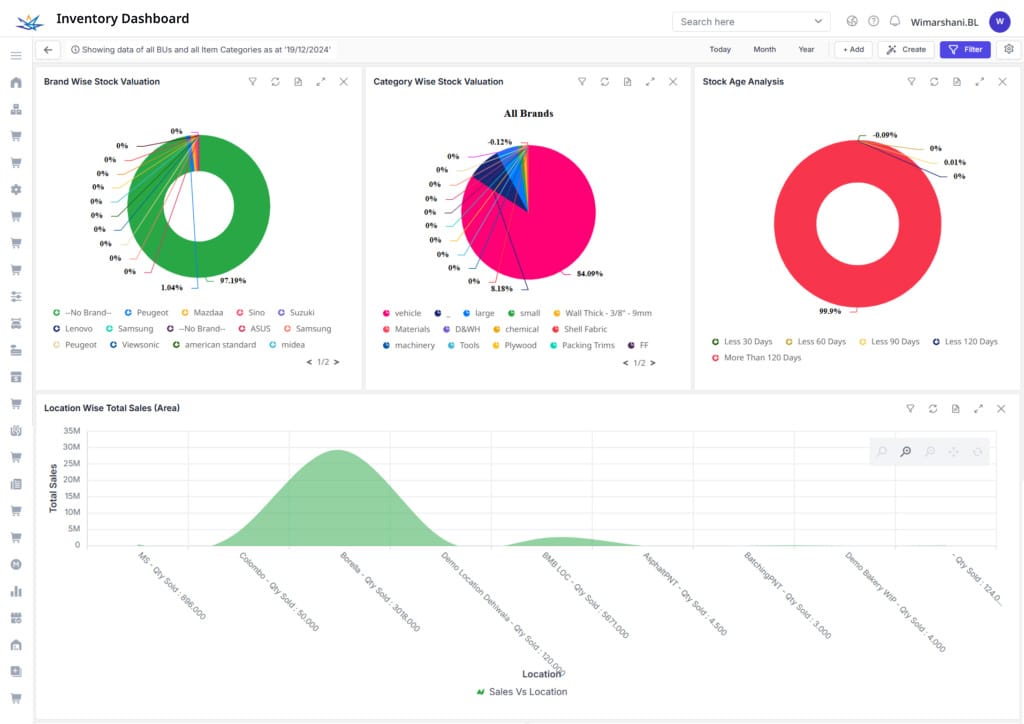

Better Inventory Management

Real-time tracking and visibility of inventory levels help in maintaining optimal stock levels, reducing overstocking and stockouts.

Scalability and Flexibility

A robust WMS can scale with your business, accommodating growth and adapting to changing business needs.

Cost Savings

By improving operational efficiency and reducing errors, a WMS can lead to significant cost savings in labor, inventory management, and order fulfillment.

Regulatory Compliance

A WMS helps ensure compliance with industry regulations by maintaining accurate records and providing traceability of goods.

Contact Us

Have questions about Warehouse Management System? Our team is here to assist you. Fill out the form, and we’ll get back to you promptly. Let’s explore how we can help drive your business forward in the UK!

Frequently Asked Questions

Get Answers to Common Questions

1. What is Blue Lotus 360 Warehouse Management System (WMS)?

Blue Lotus 360 WMS is an advanced software solution designed to optimize warehouse operations, improve inventory accuracy, and streamline order fulfillment processes. It helps manage everything from receiving goods to shipping, enhancing productivity and reducing operational costs.

2. Why do we need a warehouse management system?

A WMS is needed to improve operational efficiency, reduce errors, and enhance customer satisfaction. It automates manual processes, ensures real-time inventory tracking, and optimizes workflows, leading to cost savings, better productivity, and streamlined supply chain management.

3. Can this warehouse management system support multiple warehouse locations?

Yes, Blue Lotus 360 WMS is scalable and flexible, enabling businesses to manage multiple warehouse locations efficiently. The system provides a centralized view of inventory, allowing seamless tracking across various sites.

4. What are the four types of WMS?

The four types of Warehouse Management Systems (WMS) typically include:

- Standalone WMS: Focuses solely on warehouse functionalities like inventory tracking and order management.

- Integrated ERP WMS: Part of an Enterprise Resource Planning system for broader business management.

- Cloud-Based WMS: Hosted on the cloud, providing flexibility, scalability, and real-time access.

- Supply Chain Module WMS: Integrated with supply chain systems to optimize end-to-end logistics.

5. What is the main function of warehouse management?

The main function of warehouse management is to efficiently manage the storage, movement, and tracking of goods within a warehouse, ensuring accuracy, reducing operational costs, and improving order fulfillment speed.

6. What are four benefits of a warehouse management system?

- Improved Accuracy: Reduces errors in inventory tracking and order processing.

- Enhanced Productivity: Automates routine tasks, freeing up staff for strategic operations.

- Cost Savings: Optimizes workflows and minimizes waste, reducing overall expenses.

- Better Inventory Management: Provides real-time visibility into stock levels, preventing overstocking or stockouts.